Trivalent Chromium Zinc-Nickel Alloy Plating

cyanide-free alkaline plating solution

The main chemical suppliers for Spring Profit’s zinc-nickel alloy plating product series are MacDermid and Coventya, who are well-known specialty chemicals suppliers. Spring Profit promotes the use of cyanide-free chemicals for the electrodeposition of zinc-nickel alloys during the plating process.

Compared to traditional zinc-plated products, Spring Profit’s products are more aesthetically pleasing in terms of appearance and color, while at the same time providing enhanced corrosion resistance, thermal resistance, and weather resistance, meeting the requirements of many automotive factory specifications and RoHS requirements, to become the choice product of many customers.

Description

Trivalent chromium zinc-nickel alloy provides uniform coating thickness and exceptional coverage. The coating has low internal stress and good ductility, which allows for various current densities, and may be applied to a wide range of products.

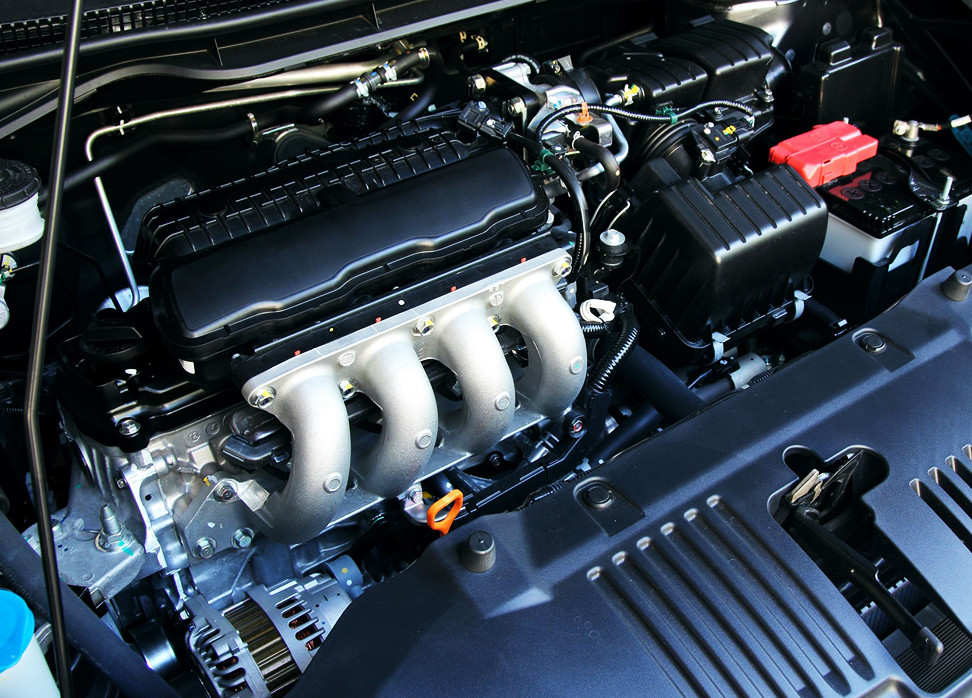

Its surface characteristics allow the fastener to be used in high temperature environments, such as fasteners for engine use. Its strengthened protection against corrosion allows the fastener to be used on automobiles. As for aluminum products, a zinc-nickel alloy surface finish provides minimal galvanic corrosion, as the smaller difference in electrochemical potential between the two metals delays the corrosion of aluminum.

Advantage

- Highly uniform coating thickness

- Glossy finish

- Excellent corrosion resistance

- Superior thermal resistance

- Friction coefficient may be adjusted according to customer requirements

- Resistance to corrosion: up to 2,000 hours (according to customer requirements)

- Plating thickness: 3um - 20um (according to customer requirements)

- Nickel content: 10% - 17% (according to customer requirements)